Fast Fashion is the production, design, and distribution of catwalk trends and high fashion designs into daily use for retail customers to take advantage of trends.

How has Fast Fashion Impacted the Garment Industry?

It is no surprise to anyone that the garment industry is ever- evolving and constantly dishes out something new and varied.

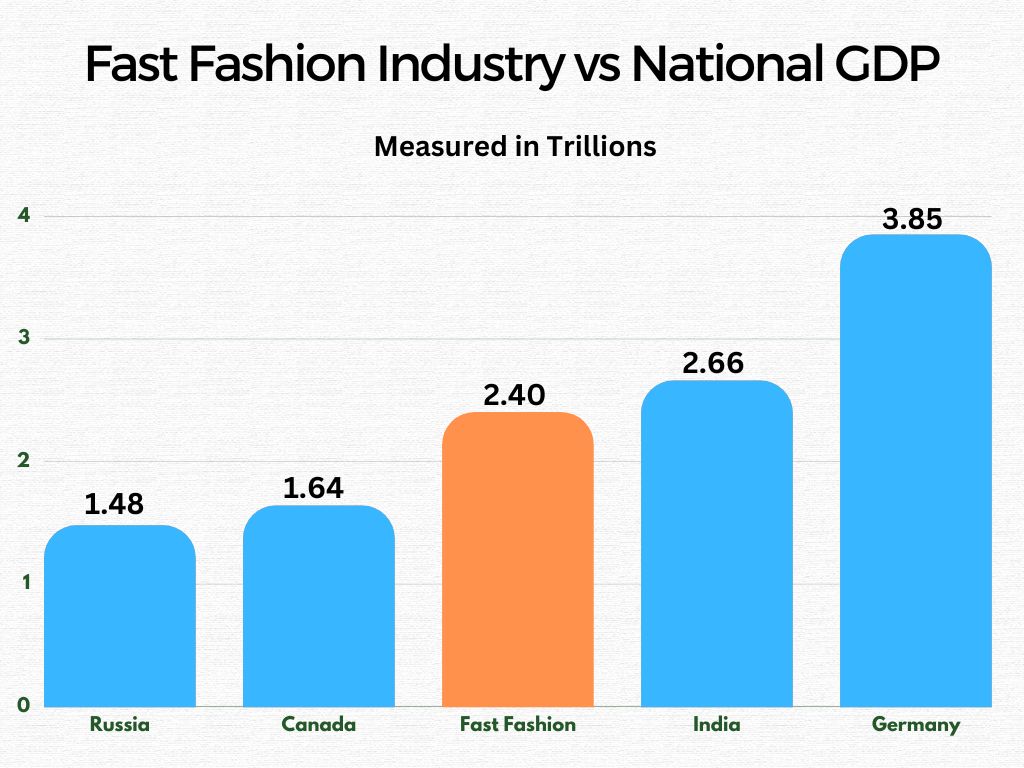

Consumers now want their favorite brands to offer new styles that match the emerging trends. The rapid growth in the trillion dollar garment industry is happening because the average customer is spending more.

Fast fashion clothing is based on the current fashion trend that goes straight from the fashion ramp to retail stores.

This kind of fashion trend satiates people’s constant desire for something new. It helps them discard the old and keep up with the latest style and taste.

This obviously means mass manufacturing of clothes as well as thinking out of the box, to come up with something new each time.

Here’s how fast fashion affects the clothing industry:

Need to make cost-effective apparels

Fast fashion implies tremendous product variety and very short product life cycles.

This, in turn, means a pressure to be cost-effective in the production of new apparels, all the while being responsive to ever-changing customer taste.

A Quick response method

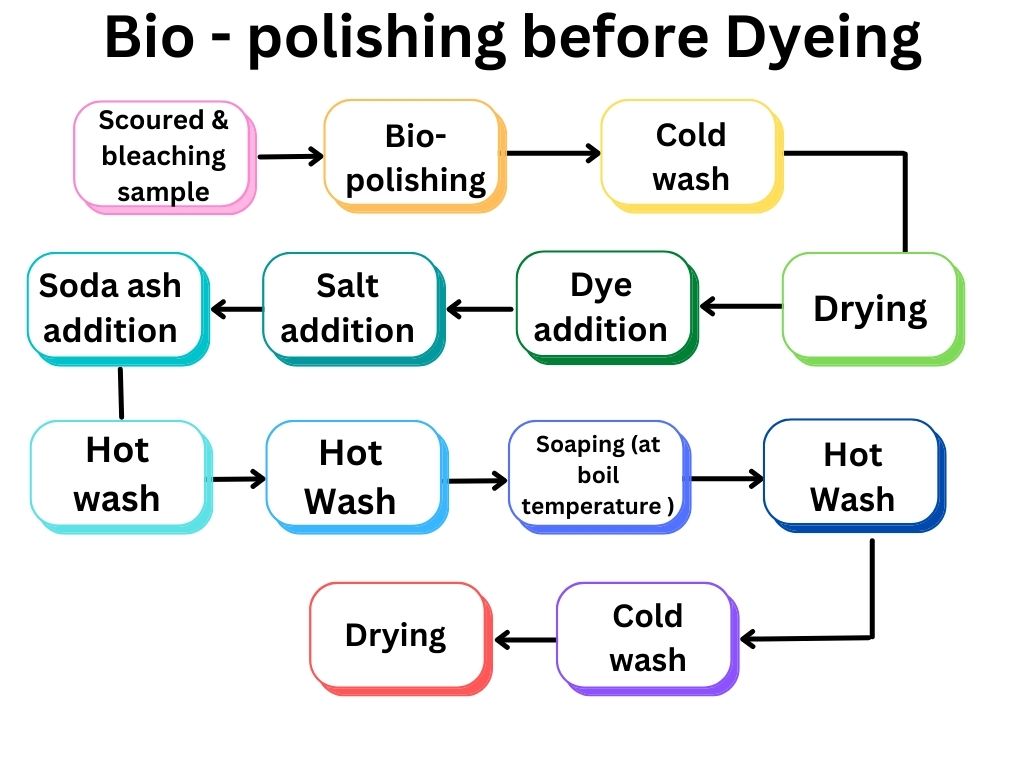

Another thing that needs to be paid attention to is the manufacturing processes. Since the competition is so strong, the lead time has to be reduced in order to keep up with the growing demand and its fast pace.

The crux of this fashion model is to shorten the time cycle from production to consumption so that consumers engage in more cycles in any given time period.

Emerging market trends

Fast fashion is promoted as a fast, low-priced and disposable form of fashion.

It is promoted as something that is consumed on the go and is quickly replaced by something new. This requires a cost-effective marketing strategy that creates brand awareness and ropes in customers.

Even if fast fashion has increased accessibility to the newest trends and made clothing more affordable, it nevertheless has drawbacks of its own.

Fast Fashion Environmental Impact

Fashion is the second most polluting industry in the world. The output has multiplied thanks to low production costs.

Demand growth has increased the use of hazardous and poisonous chemicals, which has exacerbated water pollution and resulted in around 3/4 of the clothing being disposed of in landfills.

Low Wages

To keep the production costs down, brands are hiring workers at low wages. Production is done in countries like India, Bangladesh, China, & Turkey.

Safety regulations are also not taken properly into consideration.

Demise in Second Hand Clothes Trade

The possibility of clothing being reused is disappearing due to declining clothing quality. Only around 40 percent of all clothing is useful, while the remainder is shredded after a few uses and returned to landfills.

Even though fast fashion has had both positive and negative effects, new developments are still being made every day in the fashion business for the benefit of the environment.

Are you keen on matching pace with what’s new in the garment industry?

Visit Gartex Texprocess India, a leading textile and garment exhibition in India, held in Pragati Maidan, New Delhi and Jio World Convention Centre, Mumbai, and learn about the latest technology, cutting-edge equipment, materials, and services in the industry.