3 Popular Forms of Direct to Garment (DTG) Printing

Direct-to-Garment (DTG) Printing is the technique used to print ink directly on to the fabric using ink jet technology.

Direct-to-Garment Printing or DTG Printing took the textile industry by storm in the early 2000s as decorated apparels started flooding the market.

These days they are most commonly referred to as custom t-shirt business.

This trend has been selling like hot cakes for over a decade and putting custom design on cotton shirts still continuous to be a rage.

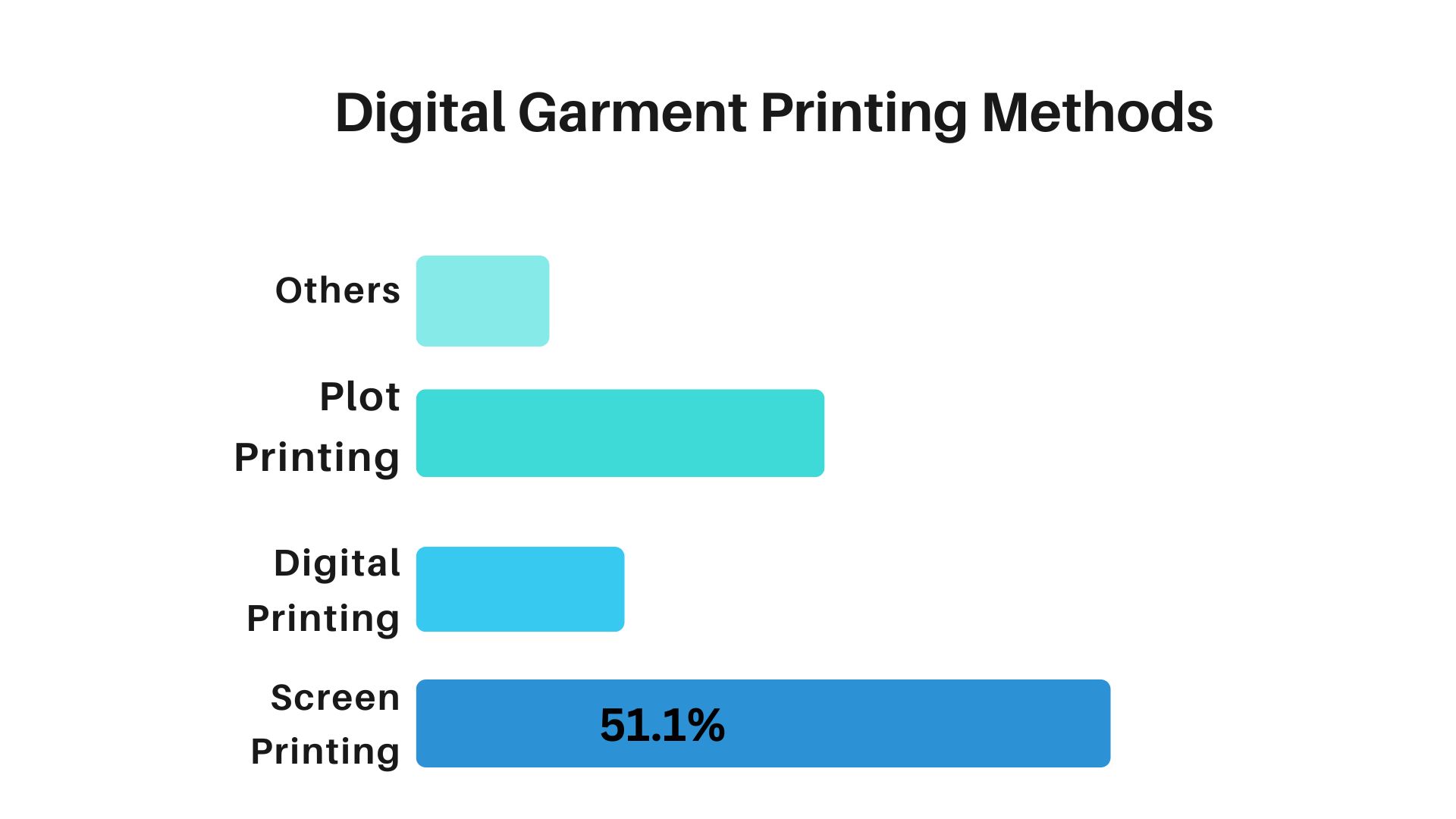

There are few decorating methods used for digital printing on clothes.

Heat Transfers

These digital transfers are designs that are printed out on a specialty paper. It only permits making one T-shirt via a standard desktop inkjet or laser printer.

The cost for each transfer depends solely on the type of ink and paper that is used by your printer.

Fabrics with such print have a plastic feel on their design which is basically a polymer used to glue the ink to the top of the shirt.

Screen Printing

The method that was once most commonly used for decorating apparels was screen printing.

There is no scope of discoloration and rectangle effect with this form of printing, as ink is only put on the garment where the design is.

The downfall that this method has is the tedious process it follows. One needs to break the graphic into the different colors needed to print it and burn the screen for each color.

This complex process also requires a screen printing press to be set up.

The New DTG Printer

The growing changes in the apparel manufacturing industry and the increase in demand have paved way for faster methods of screen printing.

Digital Garment Printing is not just more practical but also better suited for the present market.

This method requires the use of putting ink on the fabric without the usage of polymer to bind it.

The textile water-based ink, used in the process has chemical binders; it is later cured to the garment using either a heat press or a textile conveyor dryer.

Are you keen on matching pace with what’s new in the garment industry?

Know more about advancements in Direct-to-Garment (DTG) Printing on fabrics. Visit Gartex Texprocess India, a leading textile and garment exhibition in India, held in Pragati Maidan, New Delhi and Jio World Convention Centre, Mumbai, and learn about the latest technology, cutting-edge equipment, materials, and services in the industry.

More News

Rural India’s Design Labs: Where Craft Meets Contemporary

The overlooked rise of design innovation beyond urban India In the vast, textured fabric of India's garment and fashion industry, the story…View More

India’s Evolving Role in Global Apparel Supply Chains

In the last few years, global apparel supply chains have been tested like never before. From pandemic-related disruptions to rising geopolitical tensions…View More

Quality Control in Garment Manufacturing: What’s Changing in 2025?

In 2025, garment manufacturing is entering a new era—one defined not only by speed and scale, but by precision, consistency, and sustainability.…View More

How to Identify Authentic Indian Handloom Products?

Indian handloom products are a timeless testament to the country’s rich cultural heritage and craftsmanship. From luxurious Banarasi silks to timeless Khadi…View More

How to Start a Garment Manufacturing Business in India?

India’s textile and garment industry has always been a major contributor to the country’s economy, offering vast opportunities for entrepreneurs. With the…View More

Download

Register Now

Recent Posts

Show Countdown

DELHI

Bharat Mandapam (Pragati Maidan), New Delhi, India

- days

- Hours

- Minutes

- Seconds

MUMBAI

Bombay Exhibition Center, Mumbai